Disaster Recovery Services

After a hurricane, major storm or flood, what should a fuel storage tank operator do?

If your UST or AST facility has been impacted by a major weather event, such as a hurricane, Superstorm, or flood, there are a number of steps you should consider taking in order to protect your site. These practices will help you minimize the destruction to your site and assist you in safely returning the facility to operation as quickly as possible.

Our technical experts assisted the EPA in the development of a 2010 publication dedicated to the topic of USTs and floods. It is titled Underground Storage Tank Flood Guide. Many of the suggestions here were drawn from this document.

If your UST site is without power:

If flooding or standing water on the tank pad is minimal:

You should also strive to protect all vent pipes from potential damage by floating debris on the tank pad. A damaged or bent vent pipe can result in water seeping into the tank, which will create multiple additional problems.

If you ran out of fuel:

If flooding is more severe:

If your site was covered by considerable floodwater, there are many more considerations. Once you have determined that it is safe to return power to the system, consider the following actions:

- Determine if product leaked from the UST. Initially, run a static test on your ATG.

-

Verify that the leak detection system is operating properly. In addition to the static tightness test referenced above, check that the system is generally functioning properly.

-

Determine if water or debris entered the UST. We recommend you not rely on the water detection feature of the ATG, but that you manually stick the tank, using a water-finding paste on the length of the stick.

-

Verify that the leak detection system is operating properly. In addition to the static tightness test referenced above, check that the system is generally functioning properly.

-

Check that all associated equipment is functioning properly, including pumps, shear valves, fill pipes and vent lines.

-

Clean and empty spill buckets and sumps, including those under the dispensers and above the tanks. Inspect piping and fittings for damage and possible leaks.

-

Perform a UST system tightness test. You want to ensure tank and line integrity before adding fuel to the tanks.

-

Check for tank deflection, especially for fiberglass tanks, or if you have concern that the event may have impacted the structural integrity of your tanks. A bottom-flatness test provides this verification.

-

Test spill buckets and sumps to ensure tightness.

-

Test cathodic protection to ensure it is operating properly.

If your AST system was impacted:

AST operators, you are not immune to these or assorted other problems resulting from a major storm or flood. At a minimum, you should visually inspect the exterior of your tanks for any damage to the tanks, piping or associated equipment and ensure that the tank itself is free of water. If any concerns are noted, you should arrange for an inspection before returning the tank system to service.

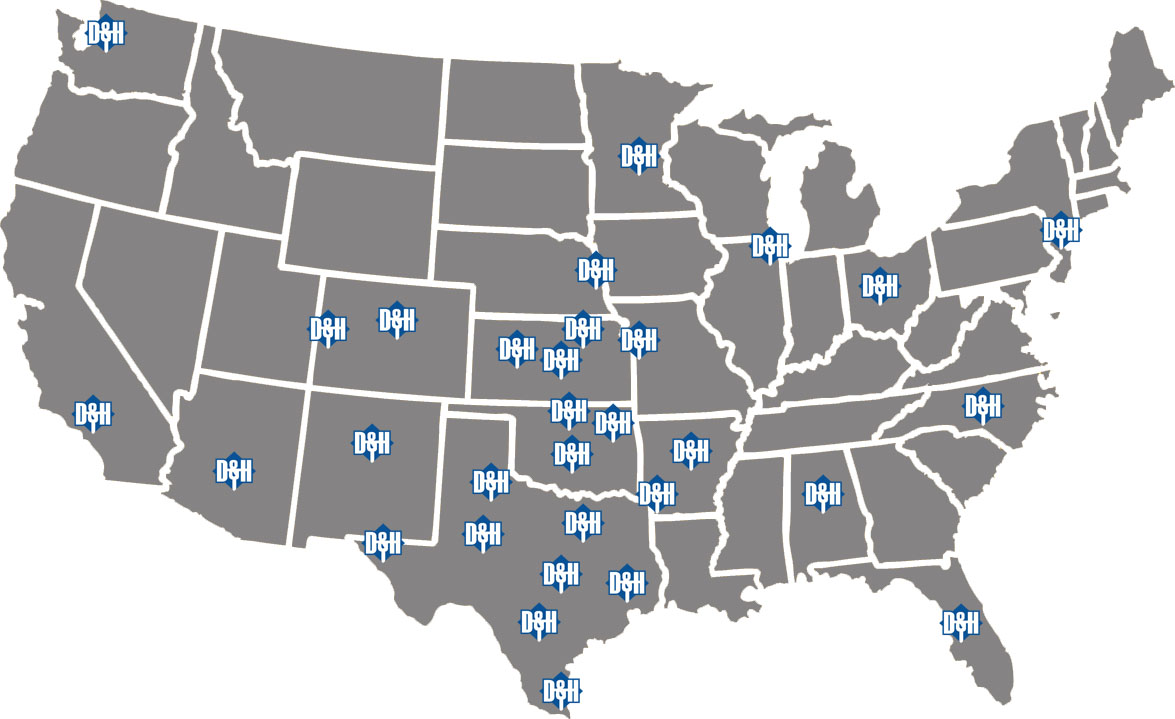

D&H United has the team and experience to help our customers prepare and recover from unplanned and natural disaster events. We work with our customer prior to potential natural disaster events to make sure that their sites are as secure and safe as possible. Afterwards we assist with the clean-up and restoration of services caused by flood or wind damage. D&H United has experience in providing temporary emergency power back-up solutions as well for those situations in which power outages are expected to last days or weeks.

To learn more, or to discuss specific needs for your site, call us today at (833) 543-0101.

Corporate Office:

8559 E North Belt

Humble, TX 77396

- Telephone: (210) 651-3882

- FAX: (210) 651-3884

- E-mail: [email protected]